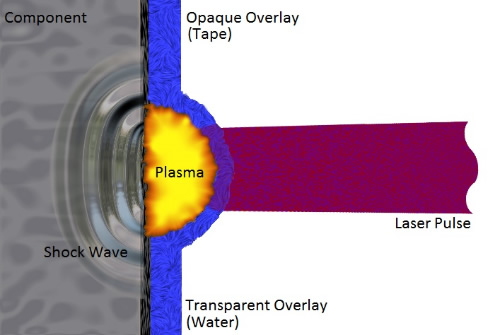

Laser shock peening technology is a kind of high and new technology, which uses the plasma shock wave generated by a strong laser beam to improve the Anti-fatigue, Anti-abrasion and anti-corrosion of metal materials. It has the outstanding advantages of non-contact, non-heat affected zone, strong controllability and significant strengthening effect. The main function of coating is to protect the workpiece from laser burn and enhance the absorption of laser energy. Commonly used coating materials are black paint and aluminum foil. The confinement layer can not only confine the expansion of plasma to increase the peak pressure of shock wave, but also extend its action time through reflection of shock wave. Commonly used confinement layer is water, K9 glass.

|  |  |