GRACE LASER TECHNOLOGY CO.,LTD.

GRACE LASER TECHNOLOGY CO.,LTD.

Grace Laser technology Co., Ltd. was founded in August of 2014, located in the Airport Industrial park, Shunyi district, Beijing. At the very beginning of its establishment, Grace Laser made clear its mission of boosting the development of the national laser industry and its vision of building the NO.1 brand of domestic laser. At the beginning of 2015, Grace Laser established a strategic cooperative relationship with the Chinese academy of Sciences(CAS), and a wholly-owned subsidiary of Xi'an was founded in 2016. In 2018, due to the strong development of the industrial market, another wholly-owned subsidiary was established in Shenzhen, mainly engaged in the production and after-sales service of industrial products. Now Grace Laser’s Beijing Headquarter, Xi'an and Shenzhen three building area of nearly 6,000 square meters, with a class 1000 optical cleanroom and assembly, production workshops. Grace Laser has passed the national high-tech enterprises, ISO9001 quality management system, ISO 13485 Medical Devices quality management system and other qualifications. Grace laser has a complete R&D, production and quality management system, committed to providing first-class laser products and services for global customers.

Grace Laser’s products are mainly used in Scientific research, Industrial processing and Medical aesthetic and other fields. Founded six years, Grace Laser has developed High power pulsed lasers (LAMBER series) used for material modification (Laser Shock Peening) and the scientific research, High power ultrafast picosecond laser (BLAZER series) used for micromachining and Medical Picosecond laser (ALICE-PS series) used for Medical aesthetics. More than 14 series and 40 models. Grace Laser has a strong R&D strength and has achieved the annual production capacity of more than 2000 lasers.

Talent team and R&D capabilities

As of December 2021, the company has 140 employees, accounting for more than 30% of them with master's degree and doctor's degree. The company's executives and technical backbones have master's degree and doctor's degree, and most of them graduated from Harbin University of technology, Tianjin University, Southeast University, University of Electronic Science and technology, Beijing University of technology, Shanghai Institute of Optics and mechanics, Xi'an Institute of Optics and mechanics, semiconductor Institute and other famous universities. They are a highly competitive management and scientific research team

Zhiqiang Cai, CTO, graduated from Tianjin University with a Ph.D. in physical electronics, has 13 years of working experience and rich experience in solid-state laser research and development. He has published 19 articles, applied for 4 invention patents and 5 utility model patents. He is responsible for the research and development of picosecond laser. In the case of foreign components embargo, he took the lead in developing 100 kHz picosecond laser in China (in 2008); he assisted in the development of high-power nanosecond green light and UV laser and transferred them to mass production.

Grace Laser is the first to achieve 100 kHz, > 100 W infrared, > 30 W UV picosecond laser transmission in China. This type of laser has been widely used in cutting brittle materials, drilling, micromachining of superhard materials and other fields. The high-energy laser developed by Grace Laser has fine beam profile, high energy and the effect of laser shock processing is better than that of similar lasers. For example, we are the only one in China that can produce VRM mode high-energy laser with output of more than 10 joules for shock peening processing. This product has performed well in a large customer's site. The customer has successfully obtained the GE processing qualification certification in the United States by using this laser and has become GE exclusive supplier in China.

In addition, the high peak power picosecond laser applied in the field of medical aesthetics has also achieved great success. The medical picosecond laser has a pulse width of less than 300ps and output of 500mJ. Under the same index, the size of this type of laser is nearly 1 / 3 smaller than that of foreign products of the same type. At present, the laser has been exported to large medical aesthetic equipment manufacturers such as South Korea and Israel.

The company's core management team has accumulated for more than ten years in the industry, has rich strategic planning and landing operation capabilities and is familiar with the domestic and oversea market demand of solid-state lasers. Relying on the deep core technology reserve, the company has defined the development direction and strategic vision of the enterprise since its establishment. Since its establishment, the strong development momentum of Grace Laser has obtained long-term financial support for the company in the market. In 2015, the company established a strategic cooperation relationship with the Chinese Academy of Sciences and became one of the industrialization companies of Xi'an Institute of Optics and machinery of the Chinese Academy of Sciences. In 2016, angel investment fund of XikeAngel was introduced. In the case of sufficient development funds, the company has increased the introduction of talents, accelerated the construction of production lines, invested a lot in leading index research and development, which provides a very favorable condition for the company to rapidly develop and occupy the market. In 2018, Grace laser successfully obtained about 100 million of Series B financing, which provided sufficient guarantee for the company to maintain the leading position in technology in R&D investment, strengthen domestic and foreign market promotion and expand production capacity.

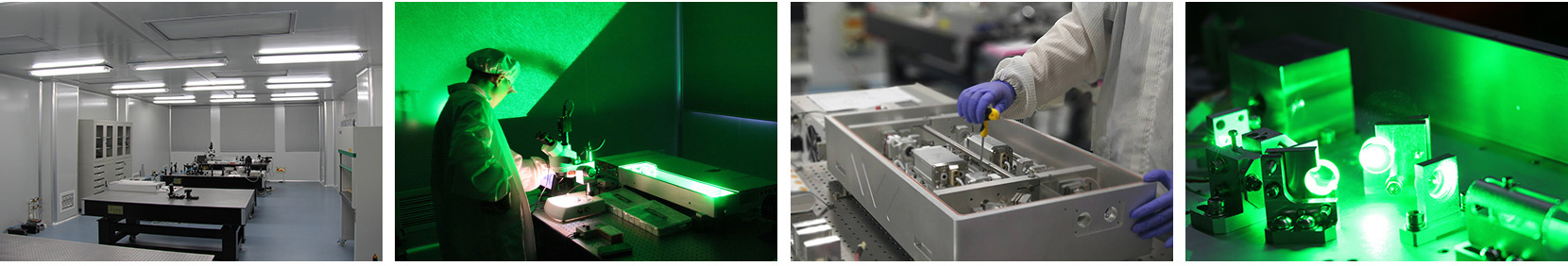

Production site and environment

Grace Laser has a class 1000 cleanroom in Beijing, Xi’an and Shenzhen. Grace Laser Beijing’s cleanroom is about 1000m², mainly responsible for R&D, customized product production and pre-production. Grace Laser Xi’an’s cleanroom is about 600m², mainly responsible for mass production of finalized products. Grace Laser Shenzhen’s lean room is about 500m², mainly responsible for the production, maintenance and application demonstration of industrial picosecond lasers.